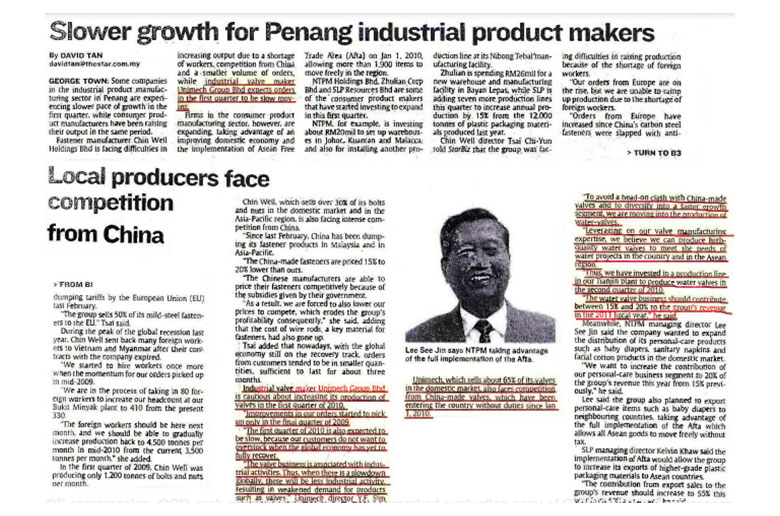

The Star I FEBRARY 8, 2010

Slower growth for Penang industrial product makers

I BY DAVID TAN I

GEORGE TOWN: Some companies in the industrial product manufacturing sector in Penang are experiencing slower pace of growth in the first quarter, while consumer product manufacturers have been raising their output in the same period.

Fastener manufacturer. Chin Well Holdings Bhd is facing difficulties in increasing output due to a shortage of workers, competition from China and a smaller volume of orders, while industrial valve maker Unimech Group Bhd expects orders, in the first quarter to be slow moving.

Trade Area (Afta) on Jan 1, 2010, allowing more than 1.900 items to move freely in the region. NTPM Holdings Bhd, Zhulian.Corp Bhd and SLP Resources Bhd are some of the. consumer product makers that have started investing to expand in this first quarter.

NTPM, for example, is investing about RM20mil to set up warehouses in Johor, Kuantan and Malacca; and also for installing another pro-dumping tariffs by the Etiropean Union (EU) East February. ‘The group sells 50% of its mild-steel fasten-ers to the EU.” Tsai said. During the peak of the global recession last year. Chin Well sent back many foreign workers to Vietnam and Myanmar after their contracts with the company expired. We started to hire workers once more when the momentum for our orders picked up in mid-2009. “We are in the process of taking in 😯 foreign workers to increase our headcount at our Bukit Minyak plant to 410 from the present 330. The foreign workers should be here next month and we should be able to gradually increase production back to 4.500 tonnes per month In mid-2010 from the current 3,500 tonnes per month.” she added.

In the first quarter of 2009, Chin Well was producing only 1,200 tonnes of bolts and nuts per month. Chin Well, which sells Over 30% of its bolts and nuts in the domestic market and in the Asia-Pacific region, is also facing intense competition from china. ‘Since last February, China has been dumping its fastener products in Malaysia and in Asia-Pacific.

“The China-made fasteners are priced 15% to 20% lower than ours. `The Chinese manufacturers are able to price their fasteners competitively because of the subsidies given by their government. As a result, we are forced to also lower our prices to compete, which erodes the group’s profitability consequently,” she said, adding that the cost of wire rods. a key material for fasteners, had also gone up.

Tsai added that nowadays, with the global economy still on the recovery track, orders from customers tended to be in smaller quantities, sufficient to last for about three months. Industrial valve maker Unimech Group P&L is cautious about increasing its production of valves in the first quarter of 2010. “Improvements in our orders started to pick up only in the final Quarter of 2009. ‘The first quarter of 2010 is also expecyed to be slow, because our customers do not want to overstock when the global economy has yet to fully recover.

“The valve business is associated with industrial activities. Thus, when there is a slowdown globally, there will be less industrial activitivy resulting in weakened demand for products such as valves” Unimech director Y.F. Sim says.

Unimech, which sells 65% of its valves in the domestic market also faces competition from China-made valves, which have been entering the country without duties since January 1, 2010.

‘To avoid a head-on clash with China-made valves and to divers’ owt segment, we are moving into thefl nromiirtinn of “Leveraging on our valve manufacturing expertise, we believe we can produce high-quality water valves to meet the needs of water projects in the country and in the Asean region. Thus we have invested in a production line in our Tianjin plant to produce water valves in the second quarter of 2010. ’The water valve business should contribute between 15% and 20% to the group’s revenue in the 2011 fiscal year,’ he said.

Meanwhile, IITPM managing director Lee See Jin said the company wanted to expand the distribution of its personal-care products such as baby diapers, sanitary napkins and facial cotton products in the domestic market “We want to increase the contribution of our personal-care business segment to 20% of the group’s revenue this year from 15% previously.” he said.

Lee said the group also planned to export personal-care items such as baby diapers to neighbouring countries, taking advantage of the full implementation of the Afta which allows all Asean goads to move freely without tax. SLP managing director Kelvin thaw said the implementation of Afta would allow the group to increase its exports of higher-grade plastic packaging materials Is to Asean countries. ‘The contribution from export sales to the groups revenue should increase to 55%.